On 8th September 2017 the Ballast Water Management Convention (BWMC) entered into force. It included a seven-year implementation period designed to give ship owners and operators time to comply with the BWMC.

The implementation period of the BWMC expired on 8th September 2024 meaning that all vessels now must comply fully with the BWMC. In other words, ballast water treatment systems (BWTS) must be both operational and in compliance with the BWMC. Our ALPHA Wafer valve helps ship owners and operators meet these regulatory requirements by mechanically and automatically balancing ballast water, even under fluctuating pressure conditions.

One of the issues we often hear about in connection with BWTS breakdowns is that high pressure from ballast pumps damages the BWTS. The ALPHA Wafer valve is a simple and low-cost solution to this problem.

According to ship owners and operators, the demand for the ALPHA Wafer valve can be attributed to three key benefits:

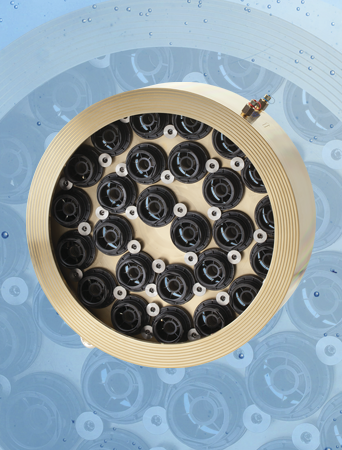

“We are of course delighted that we see this increased interest in the ALPHA Wafer valve, although, we are not really surprised. This is a sophisticated and high-quality valve, designed with a strong focus on every detail, including the valve housing made of nickel aluminum bronze in our own foundry in Slagelse, Denmark”, says Rasmus Frimann Nielsen, Product Manager at Frese.

If you have questions about the ALPHA Wafer or would like to learn more about how it can benefit your BWTS installation, please don't hesitate to reach out.

Contact us Read more about Frese ALPHA Wafer