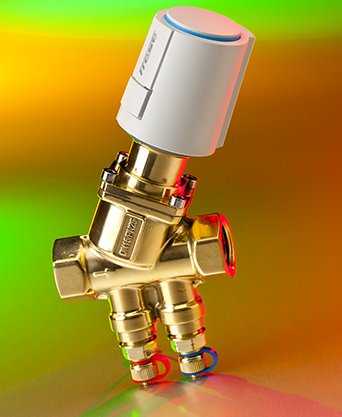

OPTIMA Compact

Pressure independent control valve

Designed to combine automatic balancing and full modulating control regardless of the preset flow.

The innovative design of OPTIMA Compact introduces an intelligent control valve that adjusts automatically to the preset flow in order to provide full modulating control. When the installer presets the valve according to the maximum designed flow, the stroke of the control valve remains the same thus providing 100% modulating control.

In practical terms, OPTIMA Compact ensures that there is no overflow and that below the design flow the actuator has absolute authority. Furthermore, OPTIMA Compact combines all those features that are necessary to ease the work of designers and installers:

- The wide (up to 800kPa) differential pressure range meets the requirements of most applications

- The compact design and the user-friendly presetting unit guarantee easy installation and commissioning.

OPTIMA Compact pressure independent control valve (PICV) is used in heating and cooling systems with Fan Coil Units, Chilled Beams or other terminal unit applications. OPTIMA Compact provides modulating control with full authority regardless of any fluctuations in the differential pressure of the system. It combines an externally adjustable automatic balancing valve, a differential pressure control valve and a full authority modulating control valve. 100% control of the water flow in the building is achieved easily, while creating high comfort and energy savings at the same time.

An additional benefit is that no balancing is required if further stages are added to the system, or if the dimensioned capacity is changed. Energy saving due to optimal control, lower flow and pump pressure. Maximized ΔT due to faster response and increased system stability.

Frese Academy - Learn more about OPTIMA Compact Actuators

Benefits

Design

- Less time to define the necessary equipment for a hydraulic balanced system (only flow data are required)

- No need to calculate valve authority. Always one.

- Flexibility if the system is modified after the initial installation

Installation

- No further regulating valves required in the distribution pipework when OPTIMA Compact is installed at terminals.

- Total number of valves minimized due to the 3-in-1design

- Minimized commissioning time due to automatic balancing of the system

- No minimum straight pipe lengths required before or after the valve.

Operation

- High comfort for the end-users due to high precision temperature control

- Longer life due to less movements of the actuator

Features

- The presetting function has no impact on the stroke; Full stroke modulation at all times, regardless the preset flow.

- The constant differential pressure across the modulating control component guarantees 100% authority.

- Automatic balancing eliminates overflows, regardless of fluctuating pressure conditions in the system.

- Thermal actuator On/Off or 0....10V, normally closed.

- Electro mechanical actuator 0-10 V and 3 point control, normally closed

- Differential pressure operating range up to 800 kPa

- High flows with minimal required differential pressure due to advanced design of the valve

- Small dimensions due to compact housing

- Higher presetting precision due to stepless analogue scale

Frese OPTIMA Compact DN10-DN32

Male/Male (excl. modulating actuator)

1200C, PN25, DZR (Couplings for OPTIMA Compact on page 24)

Category Frese no. Dimension Stroke Maximum flow Price

DN l/h

G 53-1300 10 Low flow 2.5 30 - 200 22.40

G 53-1309 10 Low flow 5.0 65 - 370 22.40

G 53-1302 15 Low flow 2.5 30 - 200 25.70

G 53-1310 15 Low flow 5.0 65 - 370 25.70

G 53-1304 15 High flow 2.5 100 - 575 25.70

G 53-1312 20 High flow 2.5 100 - 575 29.90

G 53-1308 20 High flow 5.0 220 - 1330 29.90

G 53-1313 25 5.5 600 - 3600 41.80

G 53-1314 32 5.5 550 - 4000 47.10

Male/Male with 1” P/T plugs (excl. modulating actuator)

1200C, PN25, DZR (Couplings for OPTIMA Compact on page 24)

Category Frese no. Dimension Stroke Maximum flow Price

DN l/h

G 53-1320 10 Low flow 2.5 30 - 200 25.70

G 53-1329 10 Low flow 5.0 65 - 370 25.70

G 53-1322 15 Low flow 2.5 30 - 200 28.50

G 53-1330 15 Low flow 5.0 65 - 370 28.50

G 53-1324 15 High flow 2.5 100 - 575 28.50

G 53-1332 20 High flow 2.5 100 - 575 33.20

G 53-1328 20 High flow 5.0 220 - 1330 33.20

G 53-1333 25 5.5 600 - 3600 43.90

G 53-1334 32 5.5 550 - 4000 49.20

Female/Female (excl. modulating actuator)

1200C, PN25, DZR

Category Frese no. Dimension Stroke Maximum flow Price

DN l/h

G 53-1342 15 Low flow 2.5 30 - 200 27.10

G 53-1350 15 Low flow 5.0 65 - 370 27.10

G 53-1344 15 High flow 2.5 100 - 575 27.10

G 53-1352 20 High flow 2.5 100 - 575 31.70

G 53-1348 20 High flow 5.0 220 - 1330 31.70

G 53-1353 25 5.5 600 - 3600 42.60

G 53-1354 32 5.5 550 - 4000 47.60

Female/Female with 1” P/T plugs (excl. modulating actuator)

1200C, PN25, DZR

Category Frese no. Dimension Stroke Maximum flow Price

DN l/h

G 53-1362 15 Low flow 2.5 30 - 200 30.00

G 53-1370 15 Low flow 5.0 65 - 370 30.00

G 53-1364 15 High flow 2.5 100 - 575 30.00

G 53-1372 20 High flow 2.5 100 - 575 34.70

G 53-1368 20 High flow 5.0 220 - 1330 34.70

G 53-1373 25 5.5 600 - 3600 44.70

G 53-1374 32 5.5 550 - 4000 49.70