Related products

Frese Rotary Actuators - ROL-seriesTechnical info

Images, data sheets, drawings etc.Click to download

Go to Image Bank

Related products

Frese Rotary Actuators - ROL-seriesTechnical info

Images, data sheets, drawings etc.Click to download

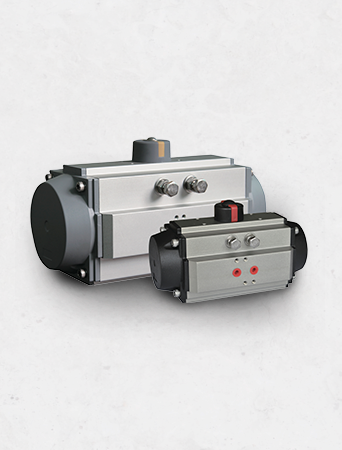

Go to Image BankPneumatic ROP-series actuators are used mainly with the OMEGA Compact 3-way Rotary Control Valves for turning the slide to open or close ports A or B. These actuators can also be used with Frese Butterfly Valves.

The double acting actuator operates in both directions using air pressure on both sides of the piston.

The single acting actuator uses air pressure on one side only to move the piston in the desired direction and the spring on the other side of the piston will place the valve slide in open or close position when the air pressure is decreased or removed.

The spring in the single acting actuator will move the valve slide clockwise or the opposite direction depending on the location of the spring in the actuator.

If a handwheel is needed a Declutchable Manual Gear. Override will be used.

ROP-series actuators are designed in accordance with the latest international standards and regulations to achieve a higher performance.

ROP-series pneumatic actuators designed and manufactured according to ISO9001.

All actuators are pressure and leak tested and externally marked with dedicated serial number for traceability.

Fully compliant with the latest international standards including ISO5211, DIN3337 and VDI/VDE3845.

Fully compliant with NUMAR standard and convenient to replace or mount accessories including solenoid valves, limit switches and all types of the brackets for the EPR positioners.

Design A single compact design utilizing identical body and end caps for both double acting and spring return models.

ROP-series piston rack and pinion design for compact construction, symmetric mounting position, high-cycle life and fast operation.

Two independent external travel stop adjustments permit easy and precise adjustment of +/- 5° in both directions.

Multiple bearings and guides on pistons and racks for precise operation, low friction, high cycle life and a blowout proof pinion shaft.

Electroless nickel-plated, bearing guided, one-piece pinion shaft for improved safety and maximum cycle life.

Reliability and high performance.

Fully compliance with all the latest international standards.

Extensive products range allows best versatility at lower price.

Innovations and patented solutions for a universal drive shaft.

Multifunction position indicator.

High precision teeth on piston racks and pinion shaft for accurate positioning, low backlash, and maximum engagement resulting in efficient operation.

Extruded aluminiumbody with both internal and external corrosion protections having a honed cylinder surface for longer life and a lower coefficient of friction.

High quality bearings and seals that provide a wide operating temperature range, low friction, and high cycle life.

Internal and external stainles steel fasteners for long term corrosion resistance.

Dedicated programme for OMEGA Compact and Frese Butterfly valves.

Higher protection level.