The project leads to annual savings of approximately 130 tonnes of fuel and approximately 400 tonnes of CO2. Next up is a similar retrofit project at the sister vessel Aura Seaways.

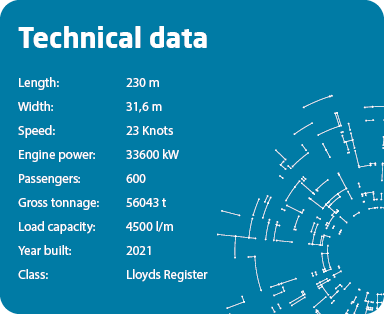

The DFDS ferry Luna Seaways and the sister vessel Aura Seaways are both RoPax ferries, carrying not only passengers but also trailers and cars. When introduced to the Frese FUELSAVE® solution, DFDS saw the possibility of reducing CO2 emissions and obtaining considerable fuel savings, and they decided to retrofit both ferries, starting with Luna Seaways.

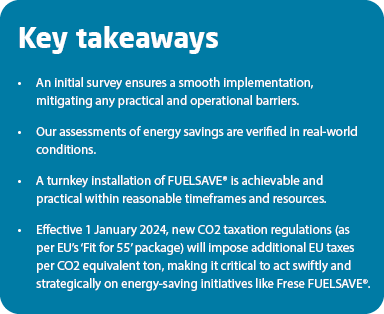

The Luna Seaways project began in March 2023, and one of the first tasks was a pre-inspection survey to determine the practical aspects of installation, including valve placement, flange compatibility, and accessibility.

The survey addressed both the mechanical and electrical aspects of the installation, and every detail – from valve installations to cable routing and control system integration – was considered to optimise energy efficiency. This ensured compatibility with existing infrastructure, minimising disruptions and maximising implementation effectiveness.

“Despite being a relatively new ferry, the survey confirmed that there was significant savings potential, and these findings have since been verified as the ferry returned to service,” says Steen Haurum, Superintendent at DFDS Luna & Aura Seaways.

The survey is optional in the FUELSAVE® solution, but – as in DFDS’ case – it builds a strong foundation for success because it is not merely a technical assessment but just as much a matter of aligning the onboard crew with the new solution. The crew often has insights of vital importance in a project of this scale, and it is important to incorporate them into the retrofit plan, ensuring not just technical feasibility but also a smooth transition.

The project was delivered as a turnkey installation of the FUELSAVE® solution, where Frese delivered the hardware, including valves, frequency converters, sensors and automation system and managed the mechanical and electrical installations.

“It’s been a well-structured process, including a pre-inspection survey and installation plan, and Frese's contribution has been fantastic, which means we are considering doing more projects in future,” says Steen Haurum from DFDS.

The installation took place during an already planned yard stay, where our team implemented the FUELSAVE® system. Post-dock, the electrical installations were completed during regular service, ensuring minimal downtime.

Luna has been at sea since September, and the FUELSAVE® system performs flawlessly and delivers the expected energy savings. Also, remote performance monitoring, as per mutual agreement, has allowed us to follow the performance after delivery and, if needed, fine-tune and optimise the system further without having to be physically onboard the vessel.

The benefits are remarkable, with fuel savings ranging from 48% to 71% depending on whether the vessel is in port or at sea. On Luna Seaways, this translates to approximately 130 tonnes of fuel saved annually, which equals an impressive reduction of 404 tonnes of CO2 emissions.

“Besides the significant fuel and CO2 reductions, the quality of the products as well as the accessibility and support from the Frese team has been excellent, and this provides us with the peace of mind that it’s a system with high reliability and long lifetime,” says Steen Haurum.

The upcoming Aura Seaways Frese FUELSAVE® retrofit project is scheduled for a preinstallation period this autumn when the vessel is at sea, while the valve installation is planned during planned docking between Christmas and New Year's. Electrical installation and commissioning will follow at the beginning of 2024 when the ferry is in operation to ensure uninterrupted service.

If you want to find out how much you can reduce CO2 emissions and fuel consumption with Frese FUELSAVE®, we’d be happy to make a business case for a specific vessel – free of charge.